Shop Roaster : Troubleshooting Heater Failure

If your Bellwether Shop Roaster has stopped heating this article will help you identify the failed component.

First we will check the heater to see if that is the failed component. Turn the roaster off and unplug the roaster from the wall.

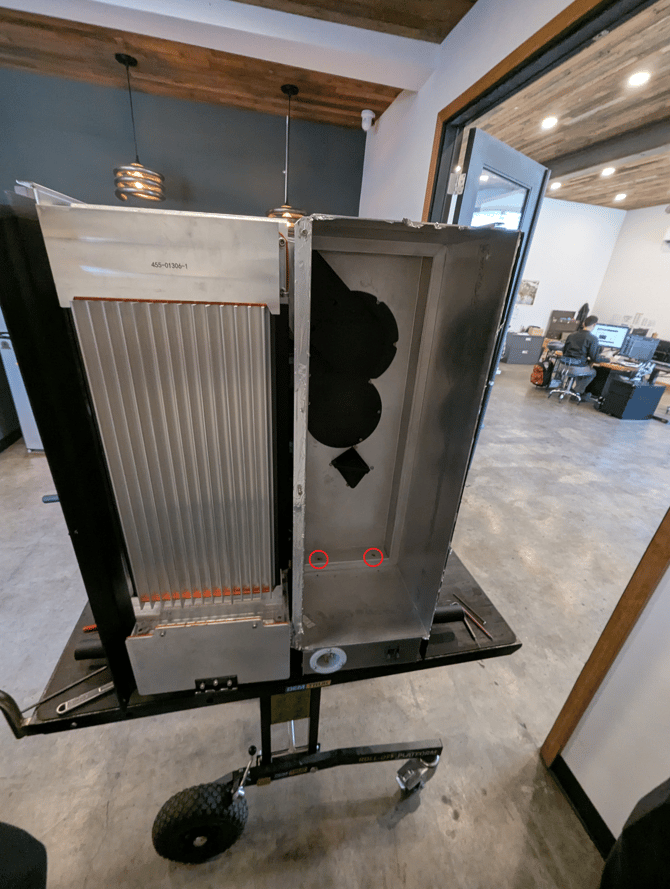

Remove the left side of roaster and look into the center of the roaster.

Using a multimeter set to resistance/ohms take a reading on both of the tan wires. The expected resistance is ~9.2 ohms. If the reading is open, the heater has failed.

If the heater has the proper resistance the next likely issue is the sense PCB or a fuse. This requires us to access the high voltage box.

To access the high voltage box follow the steps below :

1. Shut machine down and unplug from the wall.

2. Remove the Autoloader from the top of the roaster. See this guide to remove the Autoloader

3. Remove the top of the roaster.

4. Disconnect the top of the steam tube.

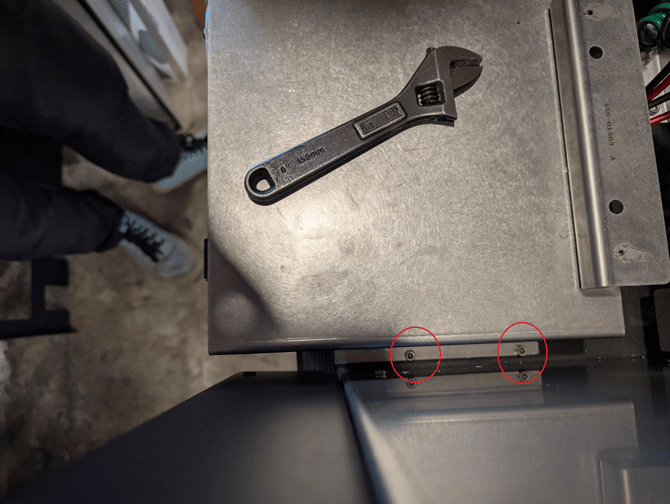

5. Remove the carbon and HEPA filter to expose the filter box housing. If screws are present here remove them.

5. Remove the carbon and HEPA filter to expose the filter box housing. If screws are present here remove them.

6. Remove the 5mm screws located on either side of the heat exchange.

7. Unplug the exhaust fans from the board. J23 and J29.

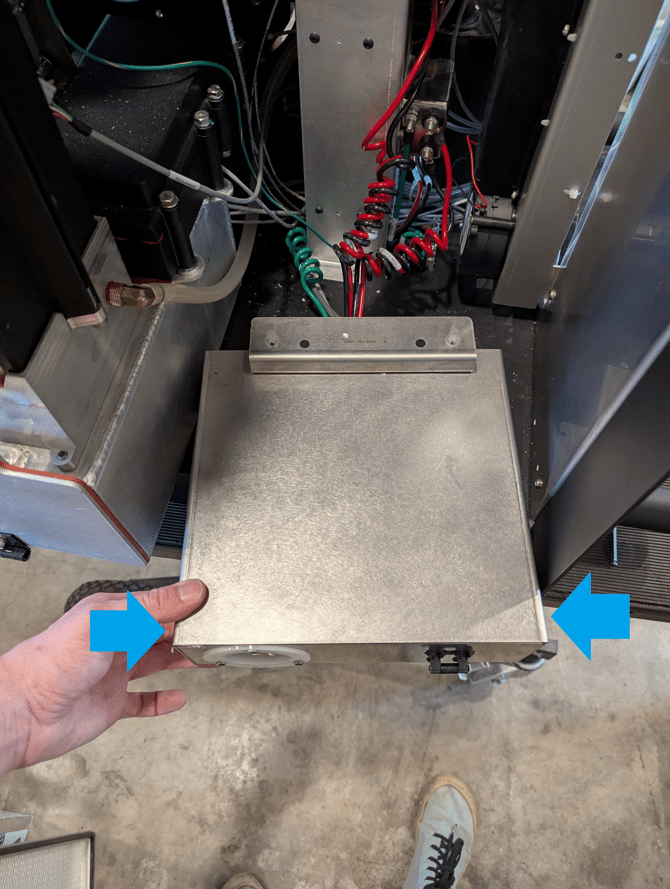

8. Lift the filter box out of the roaster to expose the high voltage box.

9. Remove the four 3mm screws (in red) holding the high voltage box down to the base plate, then remove the four 2.5mm screws (in blue) on both sides of the high voltage box.

10. You now have access to the high voltage box. If you are replacing a heater you must always inspect the Current Sense PCB (circled in red below). If the board looks singed, burnt, or damaged swap that component. If it looks fine, please leave in place and ship the unused part back to us with all other components.

With the high voltage box out you can troubleshoot the failed circuit. First test your fuses and look for any damaged to the sense pcb or the solid state relays. If no damage is found and fuses test well we would need to trace where voltage stops. Keep roaster disassembled and text/call into bellwether support to further diagnose.